SIEMENS BURNER PARTS FOR MARINE & INDUSTRY BY WIESLOCH MARINE & INDUSTRIES BV

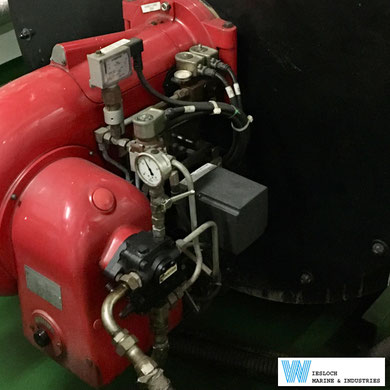

Siemens is a global leader in burner control technology, offering a comprehensive range of components for the safe and efficient operation of industrial and marine combustion systems. Whether you’re maintaining a fuel-fired boiler on board a vessel or upgrading an industrial burner installation, Siemens burner parts ensure reliable ignition, flame supervision, and fuel control under even the most demanding conditions.

At Wiesloch Marine & Industries, we supply original Siemens components including burner control units (LAL, LFL, LME, LMO), flame detectors (QRA, QRB, RAR), self-checking amplifiers (LFS1), servomotors (SQM), and accessories such as temperature controllers and socket bases. With strong availability of key models and fast delivery options, we support operators, shipyards, and service engineers worldwide.

If you need new Siemens burner parts, please send us the exact type or article number of the required part. Contact us at enquiries@wieslochmarineandindustries.com.

Siemens Burner Control Units

Siemens produces a wide range of burner control units for industrial, marine, and commercial combustion systems. These controllers manage the safe startup, operation, and shutdown of burners across oil, gas, and dual-fuel applications. Whether the system requires basic two-stage ignition or advanced modulating control with integrated air damper logic and flame supervision, Siemens offers a solution built to meet strict international safety standards.

We highlight the most commonly used Siemens burner controllers, including the LAL series for oil burners and other key product lines such as LFL, LOK, LGK, LOA, and LFE. Each series is designed for specific burner types and regulatory environments.

If you need a new Siemens Burner Control Unit, please send us the type of the burner control unit. Contact us at enquiries@wieslochmarineandindustries.com.

Siemens LAL Burner Control Units for Oil Burners

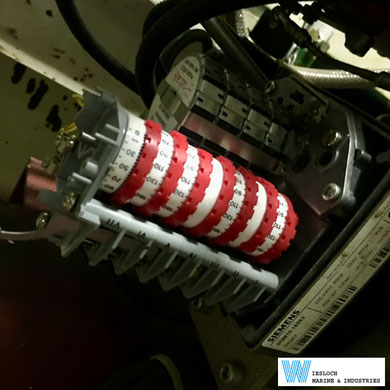

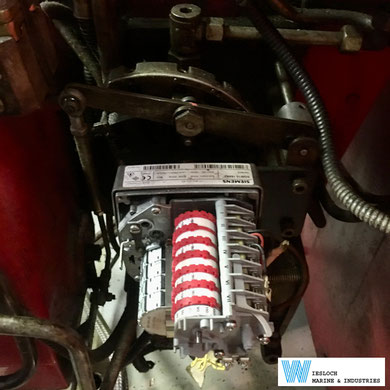

The Siemens LAL series burner control units are designed for the automatic start-up, operation, and supervision of oil burners with medium to high capacity. These controllers are widely used in marine and industrial burner systems that require a high level of safety and reliability. They are compatible with multistage and modulating burners and support both intermittent operation and monitored air damper control.

Each Siemens LAL burner controller uses a cam-driven startup sequence, meaning it follows a mechanically timed program to start the burner in a safe and controlled manner. During this sequence, the unit precisely coordinates the movement of the air damper (which regulates combustion air), the activation of the ignition system, the monitoring of the flame signal, and the staged release of fuel through one or two fuel valves. Built-in safety checks are performed at each step. These include flame signal verification (to confirm the presence of a stable flame), extraneous light testing (to ensure no false flame signal before ignition), valve position monitoring, and air pressure supervision (to verify that combustion air is present and sufficient). If any abnormal condition is detected, the controller immediately interrupts the fuel supply and initiates a lockout. The cause of the shutdown is indicated via a mechanical fault display (a rotating symbol window) and an LED signal lamp. The unit can be reset either locally by pressing the button or remotely via a control signal.

All models in the LAL series are compatible with Siemens photoresistive detectors (QRB1, QRB3), blue-flame detectors (QRC1), or photocell detectors (RAR9), depending on burner type and safety requirements. Additional features such as remote reset, external lockout indication, and galvanically separated actuator control are supported.

| Siemens Type | Typical Use | Flame Detection | Key Features | OEM Applications (Weishaupt) | Weishaupt Art. No. |

|---|---|---|---|---|---|

| LAL1.25 | Basic oil burner control | Photoresistive (QRB) or photocell (RAR) | No air pressure supervision, simple burner setups | General use in basic oil burner systems | — |

| LAL2.14 | Oil burners with air pressure supervision | QRB, QRC, or RAR detectors | Includes air pressure switch input, for yellow flame burners | Used on flash steam generators and smaller Weishaupt systems | 600175 |

| LAL2.25 | Two-stage or modulating oil burners | QRB, QRC, or RAR detectors | Air damper logic, remote reset, advanced flame supervision | Weishaupt W-FM100 platform: MS30/40, RMS50–70, RL60/70 | 600177 |

| LAL2.65 | Oil burners with extended safety prepurge needs | QRB, QRC, or RAR detectors | Longer startup/purge time for high-safety systems | Weishaupt industrial burners, heavy-oil or larger installations | 600178 |

| LAL3.25 | Custom or high-capacity burner systems | QRB, QRC, or RAR detectors | Custom timing for special burners or incinerators | Used in Weishaupt systems for waste burners and engineered solutions | 600179 |

If you need a new Siemens Burner Control Unit, please send us the type of the burner control unit. Contact us at enquiries@wieslochmarineandindustries.com.

Other Siemens Burner Control Units: LFL, LOK, LGK, LOA, LFE

In addition to the LAL series, Siemens offers a range of burner control units tailored to specific burner types, fuel systems, and safety requirements. These include the LFL, LOK, LGK, LOA, and LFE series — all widely used in industrial, marine, and commercial heating systems. Each series is engineered to meet different operational and regulatory demands, while maintaining the high safety and reliability standards Siemens is known for.

The Siemens LFL series is a versatile solution for controlling forced-draft burners that operate on gas, oil, or dual-fuel. These controllers are ideal for multi-stage or modulating burners and include built-in support for air damper actuators, pre- and post-purge sequencing, and flame monitoring via ionization probes or UV detectors such as the QRA series. Common models like the LFL1.122, LFL1.335, and LFL1.638 are frequently used in Weishaupt RL, WM-G, and WK burners, and are available with various timing configurations to match burner size and application.

The LOK and LGK series are Siemens’ burner controllers with integrated self-checking flame supervision, developed to meet enhanced safety standards such as TRD 411/412 for steam boilers. The LOK series is used for oil burners, while the LGK is designed for gas and dual-fuel systems. These units constantly verify the integrity of the flame signal circuit and are typically installed in installations where continuous operation or regulatory compliance is required. Models such as the LOK16.250, LGK16.122, and LGK16.635 offer compatibility with RAR and QRA flame detectors and are directly replaceable in many Weishaupt systems.

For compact or domestic burner systems, the Siemens LOA series remains a widely recognized solution. Although many LOA models are now considered legacy products, they are still in active use in older one- or two-stage oil burners. These compact controllers, such as the LOA24.171B27, are suitable for intermittent operation and are often replaced today with newer models like the LMO series, which retain the same footprint but offer digital performance.

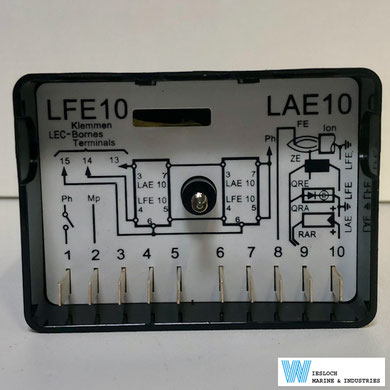

Finally, the LFE series serves niche applications where extended purge times or non-standard timing sequences are required. Functionally similar to the LAL range, LFE controllers such as the LFE10 are built for industrial oil burners with longer ignition and ventilation demands. These units are often selected for systems with customized startup requirements or where additional airflow management is critical.

| Siemens Series | Typical Use | Compatible Flame Detectors | Popular Models | OEM Usage / Weishaupt Info | Weishaupt Art. No. |

|---|---|---|---|---|---|

| LFL | Gas, oil, or dual-fuel forced draft burners; often with air dampers and modulating control | QRA2, QRA4, QRA10, Ionization |

LFL1.122 LFL1.333 LFL1.335 LFL1.622 LFL1.638 |

Used in Weishaupt modulating burners, e.g. RL or WM-G series with ionization or UV detection |

600161 (LFL1.122) 600255 (LFL1.333) 600172 (LFL1.335) 600165 (LFL1.622) 600174 (LFL1.635) |

| LOK | Oil burners requiring self-checking flame supervision (e.g. for steam boilers, TRD 411/412) | RAR9, QRA53, QRA55, Ionization |

LOK16.250 LOK16.650 |

Equivalent function to LAL but with self-checking flame amplifier for safety regulations |

600192 (LOK16.250) 600220 (LOK16.650) |

| LOA | Compact oil burner controllers for domestic and small commercial burners | QRB1, QRB3 |

LOA24.171B27 LOA26.171B27 LOA44.252A27 |

Phased out in favor of LMO; used in early RL/W burners and domestic units | Various legacy codes |

| LFE | Industrial oil burners with extended pre-purge or post-purge times | QRB1, QRB3, RAR9 | LFE10 | Used in larger oil burners where custom ignition timing is required | 600121 (LFE10) |

| LGK | Gas or dual-fuel burners needing self-checking flame supervision | QRA55, RAR9, Ionization |

LGK16.122 LGK16.333 LGK16.622 LGK16.635 |

Gas counterpart to LOK; replaces older flame safeguards with integrated self-checking |

600200 (LGK16.122) 600257 (LGK16.333) 600201 (LGK16.622) 600197 (LGK16.635) |

If you need a new Siemens Burner Control Unit, please send us the type of the burner control unit. Contact us at enquiries@wieslochmarineandindustries.com.

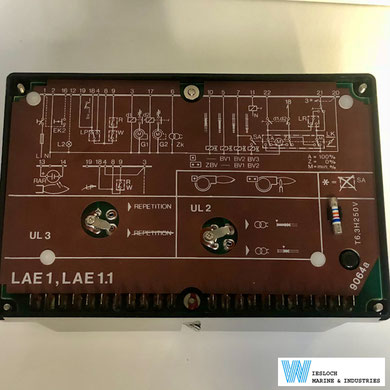

Siemens Flame Signal AmplifierS

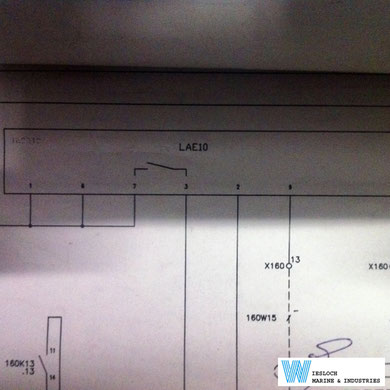

In burner installations that require external flame signal processing or enhanced supervision, Siemens flame signal amplifiers play a vital role. Units like the LAE10, LFE10, and the newer LFS1 are specifically designed to work alongside Siemens burner controls such as the LAL and LFL series. These amplifiers evaluate the flame signal from UV detectors, selenium photocells, or ionization probes and forward a clean, reliable signal to the burner controller. They are essential in multi-burner systems, dual-flame supervision setups, or installations that demand flame indication independent of ignition logic.

The LAE10 is typically used for supervising oil flames in combination with RAR selenium photocells, while the LFE10 is suitable for gas and light-oil flames, particularly when using QRA UV detectors or flame rectification probes. Both are plug-in type flame safeguards with built-in indication lamps and safety relays. In systems requiring continuous operation or enhanced safety testing (e.g. TRD 411/412 compliance), the LFS1 series offers modern functionality, built-in self-checking, and compatibility with digital Siemens burner controllers. Available in variants like LFS1.11A2 and LFS1.21A1, these units are gradually replacing older LAE and LFE models in OEM and retrofit applications.

If you need a new Siemens Flame Signal Amplifiers, please send us the type of the flame signal amplifier. Contact us at enquiries@wieslochmarineandindustries.com.

| Siemens Type | Typical Application | Compatible Flame Detectors | Key Features | Weishaupt Art. No. |

|---|---|---|---|---|

| LAE10 | Oil burners (yellow flame) | RAR7, RAR8 (selenium photocells) | Flame signal amplifier for RAR detectors, used with LEC1 or LAL controllers | 600162 |

| LFE10 | Gas burners and blue flame oil burners | QRA series (UV), rectification probe | Built-in UV tube test, for multi-flame and dual supervision systems | 600210 |

| LFS1.11A2 | General industrial burner use (replacement for LAE10/LFE10) | QRA, RAR, FE probe (configurable) | Modern flame amplifier with test functions, compatible with LME/LMO/LMV | 600276 |

| LFS1.21A1 | Continuous burner operation, dual detector inputs | QRA + RAR or FE probe | Self-checking, dual flame input, replaces LAE10/LFE10 in TRD-compliant systems | 600278 |

Siemens Flame Detectors

Flame detectors are critical components in burner safety systems, ensuring reliable flame supervision during startup and continuous operation. Siemens offers a wide range of flame sensors to match different burner types, combustion fuels, and control unit requirements. These detectors convert the optical or electrical characteristics of a flame into a signal that is evaluated by a burner control unit or flame amplifier. Depending on the burner configuration, Siemens provides UV flame sensors, photoresistive detectors, and selenium photocells, each tailored to specific use cases.

The QRA series is Siemens’ most widely used UV flame detector line. These detectors are ideal for gas and dual-fuel burners and are designed for both intermittent and continuous operation. Compact models such as the QRA10.C are often installed in modern gas burners with LME or LMV controllers, while heavy-duty types like the QRA53 and QRA55 are used in systems requiring high-safety continuous flame monitoring, typically in combination with LGK controllers or self-checking amplifiers like the LFS1 series. The QRA73 is specifically designed for LMV5 systems and allows precise UV detection in high-performance burner setups.

For oil burner applications, the QRB series provides a cost-effective and robust photoresistive detection solution. Models like the QRB1 and QRB3 respond to visible light emissions from yellow flame combustion and are compatible with controllers such as the LAL, LMO, LOA, and LME7. These detectors are commonly used in both residential and industrial burners and can be mounted with or without a protective viewing tube.

In applications involving heavy fuel oil or older system designs, Siemens also offers RAR detectors such as the RAR9. These use a selenium photocell to detect visible radiation and are often paired with LAE, LAL, or LOK controllers, especially in older marine boiler systems. Though less common today, they remain important in retrofit projects and spare part sourcing for legacy equipment.

| Type | Technology | Typical Application | Compatible Siemens Controllers | Weishaupt Art. No. |

|---|---|---|---|---|

| QRA2 | UV | Oil/gas burners, intermittent operation | LFL, LME, LFS1, LMV2/3 | 600232 |

| QRA10.C | UV | Compact burners, intermittent | LFL, LME, LMV | 600233 |

| QRA53 | UV | Continuous flame monitoring | LGK16, LGI16 | 600234 |

| QRA55 | UV | Compact burners, continuous use | LGK16, LGI16 | 600235 |

| QRA73 | UV | LMV5-specific applications | LMV5, LME75 | 600236 |

| QRB1 | Photoresistive | Oil burners, visible light detection | LAL, LME7, LMO, LOA | 600237 |

| QRB3 | Photoresistive | Oil burners with protective tube | LAL, LOA | 600238 |

| RAR9 | Selenium photocell | Heavy oil or special flame applications | LAL, LAE, LOK, LFS | 600239 |

If you need a new Siemens Flame Detector, please send us the type of the flame detector. Contact us at enquiries@wieslochmarineandindustries.com.

Siemens Servomotors

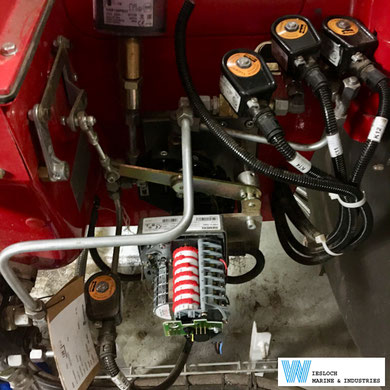

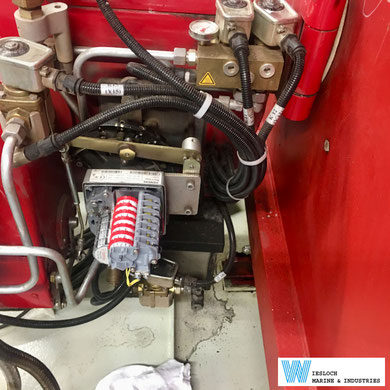

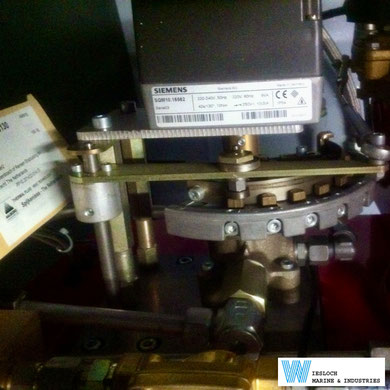

Servomotors from the Siemens SQM and SQN series are used to accurately position air dampers and fuel control valves in burner systems. They receive signals from a burner control unit and adjust mechanical components to regulate the air-to-fuel ratio throughout the combustion process. This modulation is essential in both fixed-stage and fully modulating burners, particularly in systems designed for high efficiency or variable load conditions.

The SQM10 series is commonly used in marine and industrial burners where compact dimensions, medium torque, and precise control are required. These motors are available in versions with or without integrated feedback, and with various travel angles and runtime options. They are compatible with burner management systems such as the Siemens LMV, LME, and LFL platforms. Typical applications include modulating gas and dual-fuel burners, as well as oil burners with load-dependent air control.

The SQN series includes low-torque servomotors designed for applications where smaller adjustment forces are sufficient, such as single-stage air dampers or auxiliary valve control. Despite their size, SQN motors provide reliable, repeatable positioning and are compatible with both analog and step-switching burner control signals. They are often used in compact burners or as part of multi-motor configurations.

Other SQM models, such as the SQM20, SQM40, and SQM91 series, are used in systems requiring higher torque output and longer actuator lifespans. These are typically found in large industrial boilers, incinerators, and burners operating under continuous modulation.

All Siemens servomotors are available in different mechanical configurations and electrical interfaces, allowing integration with a wide range of burner designs. Selection depends on torque requirements, travel angle, runtime, and the controller used.

| Servomotor Type | Torque Range (Nm) | Typical Runtime (s) | Travel Angle | Typical Use | Weishaupt Art. No. |

|---|---|---|---|---|---|

| SQM10 (42s, 230V) | 2.5–25 | 42 | up to 160° | Compact industrial and marine burners, air/fuel control | 651 418 |

| SQM10 (42s, 110V) | 2.5–25 | 42 | up to 160° | Compact industrial and marine burners, air/fuel control | 651 417 |

| SQM10 (20s, 230V) | 2.5–25 | 20 | up to 160° | Compact industrial and marine burners, fast modulation | 651 422 |

| SQM10 (20s, 110V) | 2.5–25 | 20 | up to 160° | Compact industrial and marine burners, fast modulation | 651 423 |

| SQM20 | 8–35 | 4–30 | up to 160° | Larger modulating burners, multiple valve control | – |

| SQM40 / SQM45 | 35–90 | 4–120 | up to 160° | High-capacity burners and process applications | – |

| SQM50 | 90–160 | 10–120 | up to 160° | Large burners, industrial boilers, incinerators | – |

| SQM91 | 40–160 | 5–120 | up to 160° | Variable-speed, intelligent control applications | – |

| SQN30.402 (230V) | 0.8–3 | 4–30 | up to 90° | Small burners, air damper positioning | 651 019 |

| SQN31.402 (230V) | 0.8–3 | 4–30 | up to 90° | Low-torque applications, residential burners | 651 039 |

| SQN45.291 B9 WH (3 Nm) | 3 | – | up to 90° | Modulating burners with W-FM100 | 651 501 |

| SQN48.497 B9 (20 Nm) | 20 | – | up to 90° | Higher torque oil/gas burners with W-FM100 | 651 503 |

If you need a new Siemens servomotor, please send us the type or article number of the servomotor. Contact us at enquiries@wieslochmarineandindustries.com.